SERVICES

We encourage innovations

to meet challenges through

our variety of services

Overview

Our services

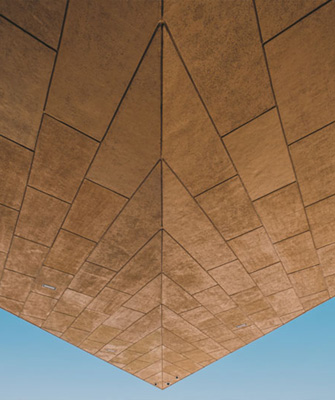

Glass fiber Reinforced Concrete (GRC)

GRC is a multipurpose construction material that has been servicing the construction industry for more than 30 years and still used in many modern projects.

GRC is approximately 80% lighter than pre-cast steel reinforced concrete cladding, offering a more comprehensive versatility because of its superior compressive strength and flexural properties. GRC is eco -friendly in comparison to pre-cast concrete (lower co2 emissions caused during manufacture).

GRC is formed by reinforcing concrete with Alkali Resistant glass fiber, then molding it into the desired form. With its high mechanical properties such as compression and flexural strength, GRC material is used in many different designs leading to its widely use in engineering, architecture and industrial fields.

Glass Fiber Reinforced Plastic (GRP)

GRP is a highly cost-effective, long-lasting, and sustainable product offering outstanding corrosion protection; GRP is highly tolerant of the most aggressive of environments. GRP’s excellent tensile strength is equal to or greater than equivalent steel profiles. Despite its lightweight properties (75% lighter than steel equivalents), GRP offers remarkable strength-to-weight load-bearing performance.

Like wood, concrete, metal, glass GRP is suitable for the intended use and can easily be customized by adding different features and with its low-cost moulds compared to other forms of material. The properties of GRP make it ideally suited for use on electrically hazardous sites. GRP, in all its forms, offers a low maintenance solution.

Glass fiber Reinforced Gypsum (GRG)

Glass-reinforced gypsum technology produces thin, lightweight, high-strength pieces for architectural applications. It is easily installed, due to its light in weight compared to traditional stone or plaster ornaments. Also, GRG is eco-friendly, as it is mineral and enhances thermal resistance of GRG, reduces the air conditioning load on the buildings, hence it reduces the operational energy need in GFRG buildings also and when exposed to flame or heat,

GRG acts as a thermal regulator protecting materials behind it from the heat of fire for up to two hours. Doha Extraco produces several glass-reinforced gypsum (GRG) plaster products engineered to meet a wide variety of specifications for architectural decoration. While our standard formulations generally meet most needs, we also can customize a special formulation for you based on your specifications for a particular application.

Exterior Insulation and Finish System (EIFS)

Ultra High Performance Concrete (UHPC)

An Exterior Insulation and Finish System (EIFS) is a non-load bearing, exterior wall cladding system that consists of an insulation board attached either adhesively or mechanically, or both, to the substrate; an integrally reinforced base coat; and a textured protective finish coat. EIFS is the “best performing cladding” concerning thermal and moisture control when compared to brick, concrete, and cementitious fiberboard siding.

UHPC is one of the latest advances in concrete technology and it addresses the shortcomings of many concretes today: It provides high strength to weight ratio, high tensile strength, high ductility, and volume stability. It has a compressive strength 2 to 3 times greater than conventional concrete and a flexural strength 2 to 6 times greater.

These mechanical properties of UHPC make it ideal for pre stressing applications. In addition to achieving high compressive strengths in excess of 25,000 psi (sometimes greater than 30,000 psi), UHPC is also nearly impermeable. UHPC consists of fiber and steel reinforced cement; the cement mixture is composed of Portland Cement combined with silica fume and fine steel filings.

UHPC was developed in Europe in the 1980s for specialized applications that demand superior strength and corrosion resistance, such as for marine applications or seismic structures. More recently, the use of UHPC has expanded to applications requiring its high strength in narrow profiles, such as bridge spans and building facades in which the material’s strength, wear resistance, lighter weight and lower life cycle costs have been the driving determinates